Expansion Joint

KUMTEK has been involved in the design,

manufacturing, and installation of high

quality, non-metallic expansion joints

kumtek offers a complete range of single

and multiple layers, fabric and fluoro-

elastomer (Viton or Fluorel) type

constructed from best and world-wide

recognized materials to overcome varied

combination of duct movement, corrosion

and particles. Up to year 2014, over 10,000 joints have been installed in power

plant, petroleum, petro-chemical, paper,

steel, incineration, semi-conductor, and

Chemical industries and gained reputation

For high quality, durability and economy. |

↑Base fabrics used

|

| Product Applications Range |

| |

Temperature: ambient to 1000°C

Flow medium: air to corrosive gas

Pressure: -30000 to 30000 Pa

Axial movement: (% of active length)

Compression --50%

Extension –10 to 20%

Lateral –5 to 15%

Above movement capabilities are standards with us.

The joints can be designed to meet specific demands. |

|

↑Hot Air Duct Expansion Joint

↑Furnace Outlet, 850°C

↑CBF-Flex

↑Fluo-Flex

|

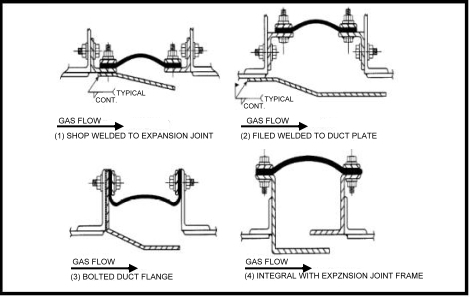

| Basic Configuration of Connection |

| There are basically 4 types of connection

between Kumtek Expansion joints and the

duct/pipe line. The choice of the connection are

usually depends on the pipe/duct designs and

on the operation conditions. Kumtek can

accommodate all connection requirements and

recommend the most suitable method for best

cost justified selection. Kumtek supply scope

covers not only the joints but also the

gasketing materials and metal parts

including, back-up bars, sleeve liners, bolts

nuts, duct flanges as well as the fabrication

and installation. |

| Expansion Joint Styles |

Based on application conditions, Kumtek offer

2 categories of Fabrics-type joints. The F series

are for corrosive flow medium and the A

series for clean air. Each series consists of 5

different styles for different service temperature

up to 1000°C. Kumtek also fabricates highest

quality fluoro-elastomer joints made of Viton

B or Fluorel, C-cure system and 100% to FSA

Standards.

F Series |

A Series |

Service Temperature °C |

F200 (Fluoro-elastomer) |

|

200 |

F250 |

A250 |

250 |

F350 |

A350 |

350 |

F500 |

A500 |

500 |

F800 |

A800 |

800 |

F1000 |

A1000 |

1000 |

|

In addition to above standard types, Kumtek can also design, fabricate to specific demands for various different application

conditions. Kumtek has the access to as well as long term Kumtek relationship with most of world-wide

recognized industrial fabrics and insulation materials manufacturers. All joints supplied

have all been proven by track records to be high-quality and most cost effective. |

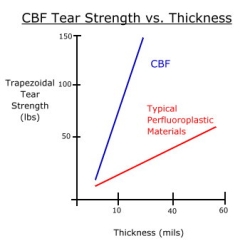

| The Corrosion Barrier Layer |

For duct/pipe with aggressive corrosion flow medium and most severe applications, Kumtek

adopts the CBF as the corrosion barrier layer.

The CBF film laminated on CBF-Flex

had been awarded both 「DuPont Plunkett」

and 「Chemical Process's Vaaler Award」 for

its outstanding structural strength and stress

cracking resistance among PTFE materials.

CBF has been considered by the industries as

the best corrosion resistance liner for expansion

Joints. With CBF film built in Kumtek expansion

Joints, you can expect:. For duct/pipe with aggressive corrosion flow medium and most severe applications, Kumtek

adopts the CBF as the corrosion barrier layer.

The CBF film laminated on CBF-Flex

had been awarded both 「DuPont Plunkett」

and 「Chemical Process's Vaaler Award」 for

its outstanding structural strength and stress

cracking resistance among PTFE materials.

CBF has been considered by the industries as

the best corrosion resistance liner for expansion

Joints. With CBF film built in Kumtek expansion

Joints, you can expect:.

*100% impermeability to corrosive gas

*much longer service life

*resist virtually all corrosive chemicals(PH 0-14)

For normal corrosive applications,

Fluo-Flex fabrics are recommended as the

corrosion barrier for economic reasons. The

Fluo-Flex series are the standard fabrics

applied by many expansion joints makers

and will also Offer you the desired

impermeability and chemical resistance as

CBF-Flex.

|

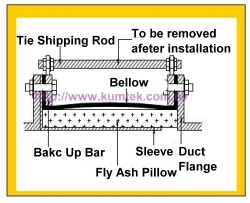

| Insulation Layer and Fly Ash Pillow |

The purpose of the Insulation and Fly Ash

Pillow are : The purpose of the Insulation and Fly Ash

Pillow are :

*Protect the joint from being damaged by fly

Ash

*Protect joint layer vulnerable to high temp.

*Reduce heat loss through joint

*Noise reduction

In Kumtek, the insulation and fly ash pillow are

designed and manufactured to meet above

requirements. All materials used including the outer

jacketing (ie. Glass cloth or steel mesh) are all

proven to be with good resistance to the flow

medium and to the high temperature through

computer thermal analysis and simulation tests to

ensure their fulfillment of above objectives.

|

| ePTFE Joint Sealant for Corrosive Duct |

Made of Expanded PTFE, Texseal Joint Sealant

are soft, pliable, and compressible offering you

the best sealing effects for corrosive gas duct. The

adhesive backing make the installation very easy. |

|

| |

|